Dye sublimation patches are a creative and versatile way to personalize items like clothing and promotional products. This guide examines the process to make dye sublimation patches DIY, covering design, printing, and finishing touches. It offers practical tips for both seasoned and beginner crafters, providing essential knowledge and practical tips for creating professional-grade patches. This versatile and vibrant method inspires creativity and innovation in the design of patches. This colorful world of creativity can be explored regardless of whether you are a seasoned crafter or a beginner.

Introduction to Dye Sublimation Patches

Dye sublimation patches are one of the most unique and durable methods of creating very bright and vibrant designs on clothing or accessories. They are made by transferring dye onto fabric with the use of a heat press or a similar device. This method ensures that the design won’t fade or wash away, making it perfect for patches that have to be able to endure time.

Dye sublimation patches offer vibrant colors, high durability, and precision reproduction of intricate designs. They also do not fade, crack, or peel, meaning that your custom creations stay fresh and bright. Unlike most printing techniques, dye sublimation infuses the color into the fabric.

Advantages of Dye Sublimation Patches

- Vibrant Colors: The color accuracy and depth achieved are unparalleled.

- High Durability: The design becomes a part of the fabric, ensuring that it lasts for a long time.

- Detail Reproduction: Excellent for designs that are highly detailed and intricate.

- Fade Resistance: Colors do not fade, even after numerous washes.

Materials and Equipment Required

The right materials and equipment are a significant part of getting professional results that pop when entering into the world of dye sublimation patches. Special equipment is required to make dye sublimation patches DIY. To start, you will require a sublimation printer, a heat press machine, and sublimation ink. You will need to make some investment in these materials because they are essential to ensure you get professional results.

Important Materials for Dye Sublimation Patches

To get started with dye sublimation patches, you’ll need sublimation ink, transfer paper, and fabric patches. These materials work together to transfer your design onto the patch, ensuring a vibrant and lasting result that showcases your creativity.

- Sublimation Ink: Specialized ink that converts to gas when heated.

- Transfer Paper: Transfers the design to the patch.

- Fabric Patches: Polyester or polyester-coated fabric works best.

- Heat-Activated Adhesive (optional): For attaching patches to clothing.

Recommended Equipment for the Sublimation Process

Having a quality sublimation printer, heat press, and design software takes your patch-making game to the next level. The equipment is sure to ensure you produce highly accurate, vibrant designs to create in the easiest, most efficient way possible. Creativity blooms at this stage – it’s when you envision bringing your creation to life on a custom dye sublimation patch.

- Sublimation Printer: This will print your design onto transfer paper.

- Heat Press Machine: It ensures that the heat and pressure are evenly transferred to the fabric for dye transfer.

Designing High-Quality Design

When designing your patch, include factors like color contrast and image resolution, along with any graphic elements, to ensure that it will turn out the best quality. Pay attention to every detail. Let your creative juices flow and come up with a patch design that is eye-catching and gives off a personal style.

Sublimation ink must be loaded in the printer before running a sublimation printing process. Adjust the settings of the printer so that they can attain the best print quality for your specific design and fabric patch. A little investment of time to get this right will guarantee a flawless print into the patch.

Choose software according to your skill level and creative needs. Adobe Illustrator and CorelDRAW offer robust tools for intricate designs, while Canva is a beginner-friendly option.

Also Read: Top 10 Creative Uses for Professionally Designed Embroidered Patches by Xpress Patches

Step-by-Step Sublimation Process

Set up a heat press to apply pressure and heat to the cloth patch once your design has been printed on transfer paper. Use sublimation transfer paper. Place the printed paper face down on the fabric patch. Use a heat press set to 380°F-400°F for 40-60 seconds. Make sure it is at constant pressure. The dye transfer is activated in this stage, creating a vivid and long-lasting design. Let the patch cool before removing the transfer paper. For best results, follow the manufacturer’s recommended time, temperature, and pressure.

Taking the Patch Shape out

When cutting out dye sublimation patches, precision is bare-bones. To guarantee neat edges, cut using sharp scissors or a craft knife. Remember that the form you cut out will determine the final appearance of your patch, so take your time and assure that precision.

Including Border and Backing Options

Consider adding backing options such as heat-activated adhesive or Velcro to your patches for a more professional appearance. Borders can help improve the appearance of your patches; choose from merrowed, hot cut, or laser-cut edges for a polished finish.

How long does the sublimation process take in making patches?

The actual sublimation process will depend on your temperature and pressure settings but usually takes 40-60 seconds per patch. However, preparation and cooling time should also be factored into your workflow.

Tips and Troubleshooting

If you experience problems such as color bleed or fading during sublimation, check your heat press settings and make sure pressure and temperature are evenly spread. Also, check that your substrate and transfer paper are compatible for the best possible outcome.

- If colors look dull, check the temperature and pressure settings.

- Uneven prints might be due to misaligned transfer paper or uneven pressure.

Pro Tips for Perfect Patch Production

Try experimenting with different substrates and textiles to create a variety of textures and effects to up your patch-making game. Remember to perform test runs prior to full production in order to optimize your workflow and polish your fixes.

Applications and Uses of Sublimation Patches

Sublimation patches can be used in many ways, from customizing apparel and accessories to branding corporate merchandise. They are also very popular in the military, sports teams, and fashion industries for their versatility and durability.

What types of fabrics are suitable for dye sublimation patches?

Materials to use include those with high content polyester, such as 100% polyester and others containing polyester, cotton, etc., which cannot be used due to the inability to react with sublimation dye.

- Customizing clothing and accessories.

- Branding promo items.

- Creating patches of a team or organization.

Can dye-sub patches be washed?

Dye sublimation patches are indeed quite resilient and durable enough for machine washing. They would not fade or crack when machine-washed, so make sure to hand-wash it on a gentle cycle using mild detergent.

Cool Ideas for Your Custom Patch Design

Get inspired by unusual patterns, gradients, and even complex details on your custom patches. This ranges from the classic designs that scream “vintage” to more modern designs featuring geometric shapes. The best is yet to come from your imagination when you make dye sublimation patches DIY.

- Vintage Designs: Retro colors and typography.

- Modern Styles: Geometric patterns or minimalist icons.

- Personal Touches: Add names, logos, or distinctive artwork.

Tips for Great Designs

- Use high-resolution images (300 DPI or higher).

- Create a strong color contrast for vibrancy.

- Add attention-grabbing elements such as gradients, textures, and borders.

Dye Sublimation Patches from Xpress Patches

Xpress Patches offers high-quality custom patch designs and embroidery at a cost-effective price. With expert professionals trained to work with designs manually, they maintain best practices and meet expectations. With years of experience, they help entrepreneurs stay ahead of trends and set themselves apart by delivering results.

Xpress Patches showcases their results through a vast clientele, which guarantees they stand out from other custom patch companies in the USA.

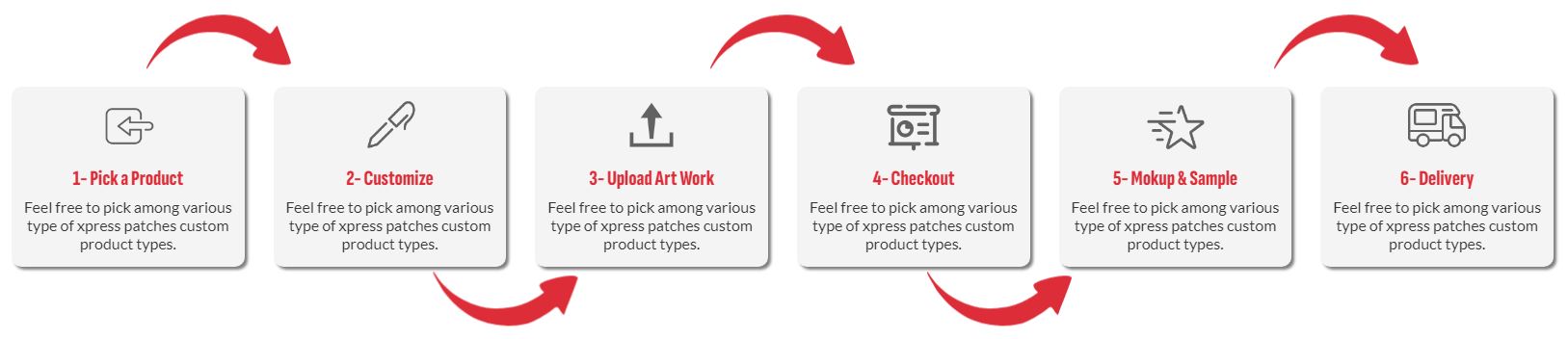

Order Process for Custom Patches

- Choose a Product – Select your preferred PVC patch style.

- Customize – Personalize the size, shape, and colors.

- Upload Artwork – Share your design or logo.

- Checkout – Confirm your order and payment.

- Approve Mockup – Review and approve the digital sample.

- Receive Delivery – Get your patches delivered.

Conclusion

Dye sublimation patches are a creative and rewarding DIY project that provides limitless customization and creativity. If one has the right materials, equipment, and techniques in design, then anybody can make unique, attention-grabbing patches for a wide range of uses. This process is ideal for personal or professional branding.

By following the guidelines and tips laid down in this article to make dye sublimation patches DIY, one can further his craft by using the vibrant and robust medium of dye sublimation patches.