Chenille patches are a timeless and stylish way of adding personality to jackets, bags, hats, and team uniforms. Known for their distinctive fuzzy texture and vibrant colors, chenille patches are popular among schools, sports teams, and even fashion brands. At Xpress Patches, we pride ourselves on creating high-quality custom chenille patches that perfectly match your vision. Today we look at the process behind creating custom chenille patches at Xpress Patches and everything you need to know about placing your customized order.

History of Chenille Patches

Chenille patches can be traced back to the early 19th century with the origins of chenille fabric, which originated in France in the 18th century. The fabric is named after the French word for caterpillar, chenille, because of its soft and furry texture. The fabric was created by weaving a “leno” fabric, then cutting it into strips to create a yarn.

Chenille patches were originally used to signify membership in prestigious organizations and universities or as a mark of distinction. They were often embroidered with tiny details.

What Do I Need to Make Custom Patches?

Chenille patches have come to represent accomplishments, community, and friendship over time. They have been used in scouting groups, military uniforms, letterman jackets, and other associations. To create custom chenille patches, you need to follow these steps:

- Design File: A high-resolution image or vector file of your design (formats like .AI, .EPS, or .PNG are common).

- Materials: Chenille yarns, base fabrics (felt or twill), and thread.

- Chenille Embroidery Machine: To craft the unique texture and design.

- Backing Materials: Depending on your preferred attachment method (iron-on adhesives, Velcro, etc.).

- Software: Digitizing software to convert designs into a stitch file readable by the embroidery machine.

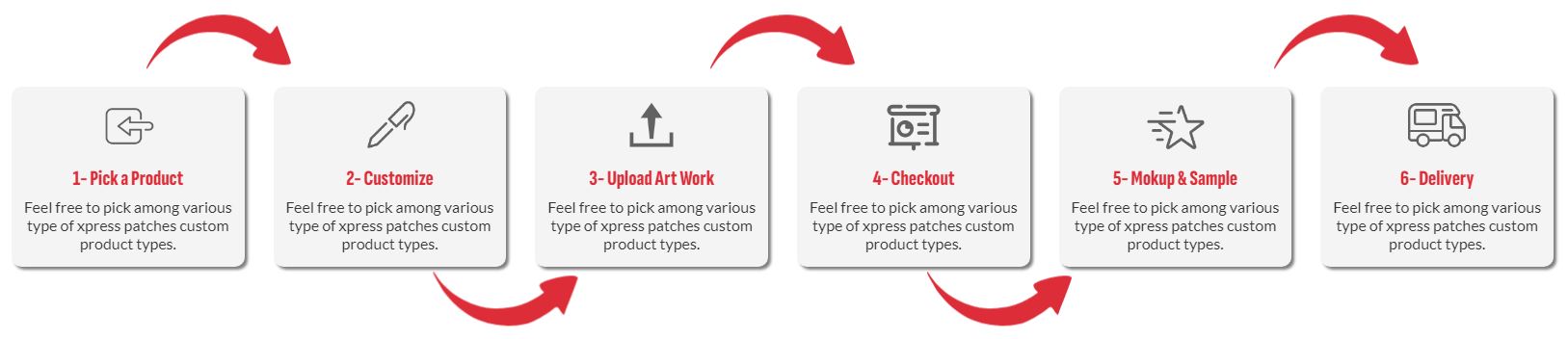

At Xpress Patches, we simplify this process by handling everything from design digitization to production.

Design Process at Xpress Patches

The journey to creating custom chenille patches begins with the design. Customers can submit their ideas in the form of sketches, vector files, or even high-resolution images. Our artists work closely with you to refine the design and make it ready for chenille embroidery. This involves finalizing the patch size, selecting colors, and choosing border styles.

1. Design Digitization

Digitizing your design converts your artwork into a format that chenille embroidery machines can interpret. To digitize a chenille embroidery design for machine embroidery, follow these steps:

- Select Machine Format: Choose a machine format that fits your embroidery machine.

- Define Shapes: Use closed shape input tools like Complex Fill combined with basic shapes (e.g., rectangles, ellipses).

- Choose Fill Patterns: Select a fill pattern compatible with chenille, such as Square or Coil.

- Set Yarn and Colors: Pick a yarn color from the palette that matches your design.

- Outline the Design: Digitize boundaries using corner or curve points for accuracy.

- Mark Entry and Exit Points: Define the path to minimize jumps and ensure smooth stitching.

- Set Stitch Angles: Specify stitch angles to achieve the desired appearance.

- Adjust in Object Properties: Finalize adjustments in the Object Properties > Compound Chenille tab.

By focusing on clear, bold lines and contrasting colors, we ensure the final product aligns with your vision. Our customer support also offers guidance on design adjustments to enhance the patch’s durability and visual appeal.

(Source: https://www.digitemb.com/blog/how-to-digitize-design-for-chenille-embroidery/)

Material Selection

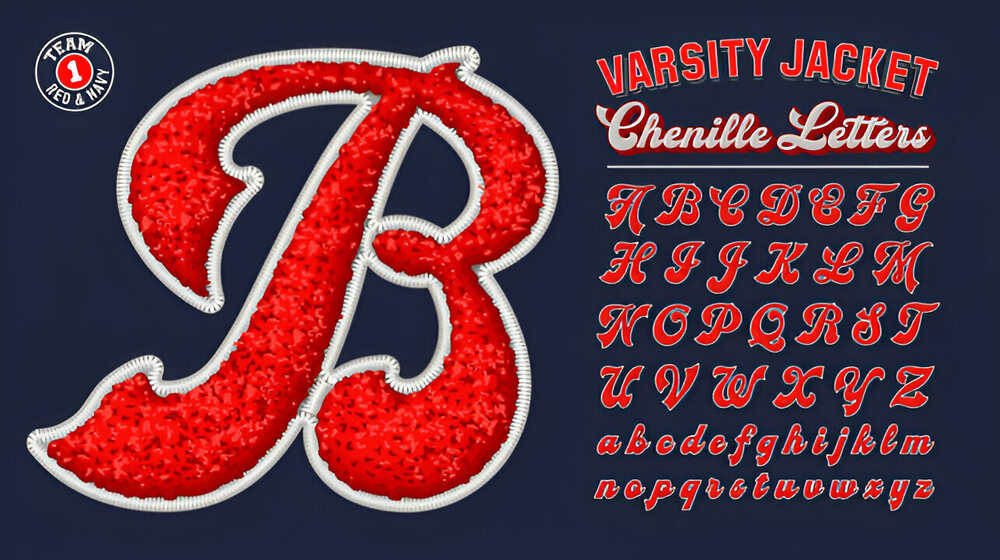

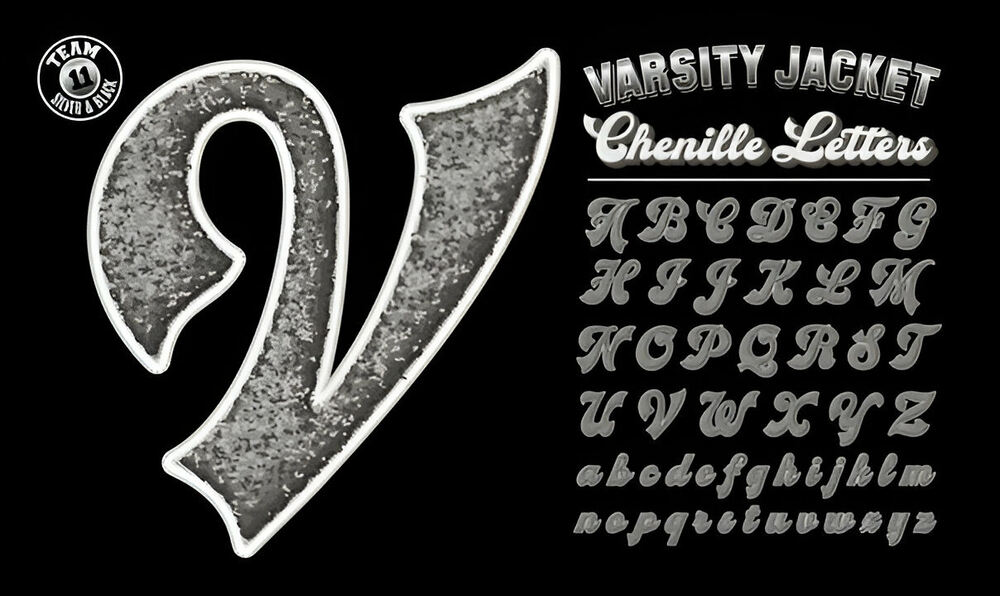

Quality begins with the right materials. Chenille patches are produced using soft and durable yarns, such as wool or acrylic, to achieve that very signature texture. The base fabric, often felt or twill, provides stability and durability, while vibrant colored threads make the patch stand out over time.

Customers can choose from a range of yarn textures and base fabric colors at Xpress Patches. Our vast material inventory guarantees that you will discover the ideal match for your project, regardless of your preference for a more muted or bright style. For those who want to add even more flair, we now have metallic and glitter yarns.

Production Techniques

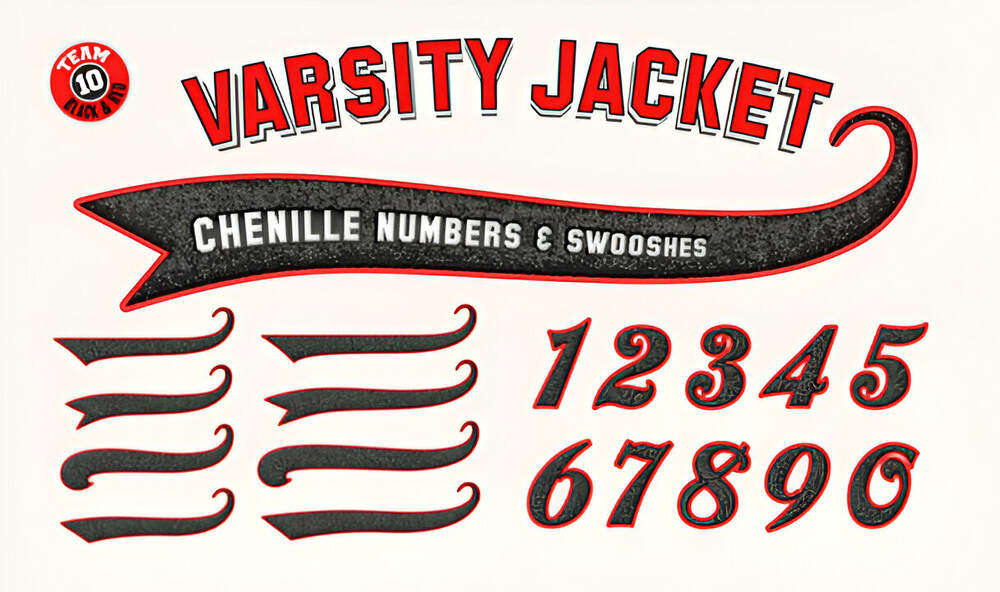

Chenille embroidery machines use specialized production techniques to create textured, raised embroidery designs, primarily using a loop or chain-stitch method. These machines and their production techniques are distinct from traditional embroidery due to their ability to produce a fuzzy, plush texture. Here are the key chenille embroidery machine production techniques:

- Chain Stitch

- Loop Stitch

- Moss Stitch

- Dual Thread Control

- Multi-Needle Functionality

- Appliqué Integration

At Xpress Patches, we use advanced chenille embroidery machines to produce each patch. These machines specialize in creating the looped stitches that give chenille its fuzzy appearance.

Backing Options

A variety of backing alternatives, including sew-on, iron-on, and adhesive backings, can be used to secure chenille patches. We provide a range of backing choices to meet your requirements:

- Sew-On Backing: Offers a permanent solution by stitching the patch onto the fabric. Perfect for clothing that is going to be washed frequently.

- Iron-On Backing: Simplifies application with heat-activated adhesive. Suitable for jackets, hats, or bags.

- Velcro Backing: Allows for temporary or interchangeable use, perfect for uniforms or items that need regular updates.

For optimal results, the surface of the patch must be clean and smooth.

Read about Iron-On vs Velcro Patches

Custom Backing Solutions

Depending on the application, Xpress Patches can also create customized solutions such as peel-and-stick backings for temporary use or magnetic patches for unique display purposes. Our team is here to help you choose the most practical option for your requirements.

Quality Control

Every manufactured patch is rigorously tested for quality defects. Xpress Patches inspects for precise stitching, accurate color matching, and adherence to your design specifications. Then the patch is tested for durability by washing and stretching, just the way the patch will undergo in the real world. For patches designed for outdoor use, they are tested for resistance to sunlight and moisture.

Packaging and Shipping

Once the patches pass quality control, they are carefully packaged to prevent damage during order delivery. Custom packaging options are available on demand for special occasions or adding a personal touch to the order. Shipping is swift and reliable, so your patches arrive on time and in perfect condition.

In line with our commitment to sustainability, Xpress Patches also offer eco-friendly packaging options. Customers can opt for biodegradable materials or minimalistic designs to reduce their environmental footprint.

Why Choose Xpress Patches?

Xpress Patches stands out for our attention to detail, advanced technology, and commitment to customer satisfaction. From assisting with design to timely delivery, we make creating custom chenille patches an exciting experience. Irrespective of the size of the order, we aim to bring your vision to life.

With large orders, discounted rates are available, and also the ability to customize every aspect of your patch, from packaging to thread types. Our dedicated customer service works on your project to make it a success.

Ready to boost your brand with high-quality, custom chenille patches?

Custom chenille patches are not just decorative; they tell a story, represent a team, or build a brand. With Xpress Patches, you get more than a product; you get a partner dedicated to quality and creativity. Contact Xpress Patches today to get started on creating the perfect patch for your needs. Let us help you make a lasting impression with our high-quality patches and exceptional service.